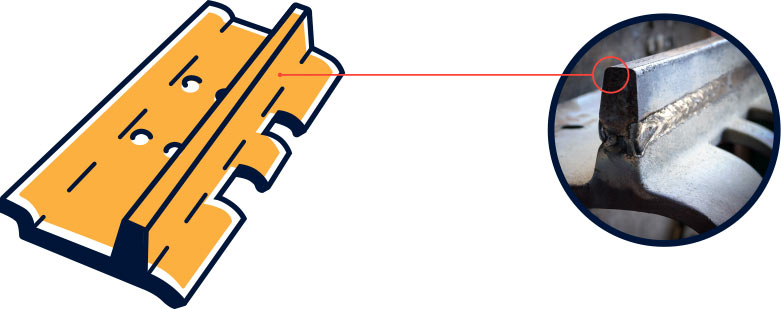

Grouser Bar For Bulldozer et Excavator

Vectis ferrea est pars metallica quae typice in machinis gravibus, ut bulldozeris et tractoriis vecturae, invenitur. Calceis ferreis adhaeret et, mordendo in terram, adiuvat ad tractionem et tenacitatem emendandam. Vectes ferreae essentiales sunt ad efficientiam machinae in locis difficilibus, ut in solo laxo aut clivis praeruptis, amplificandam. Variis formis et magnitudinibus veniunt ut variis usibus conveniant et, cum defessae sunt, substitui possunt ut optimam functionem conservent.

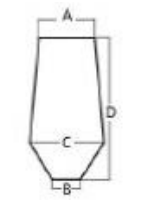

| SECTIO | A mm | B mm | C mm | D mm | Longitudo (mm) | W (kg) |

| 225 | 15 | 8 | 19 | 18 | 225 | 0.51 |

| 335 | 20 | 10 | 24 | 21 | 335 | 1.13 |

| 594 | 28.5 | 12.5 | 36.5 | 64 | 594 | 9.4 |

| DCX | 7 | 5 | 22 | 40 | DCX | 2.8 |

| 910HT-558 | 28.575 | 12.7 | 38.1 | 63.5 | 558 | 9.04 |

| 911HT-558 | XXVI.CCLXXXVII | 12.7 | 41.275 | 82.55 | 558 | 11.55 |

| 911HT-610 | XXVI.CCLXXXVII | 12.7 | 41.275 | 82.55 | DCX | 12.7 |

| ACORK3 | 10.17 | 6.35 | 19.05 | 31.75 | 76.2 | 0.28 |

| D10 | 27 | 14 | 36 | 68 | DCX | 10 |

| D10-558 | 28.58 | 14.29 | 38.1 | 66.675 | 558 | 9.5 |

| D10-610 | 28.58 | 14.29 | 38.1 | 66.675 | DCX | 10.4 |

| D11 | 27 | 14 | 41 | 82.5 | DCCXI | 15.2 |

| D12-610 | 34.925 | 12.7 | 44.45 | 76.2 | DCX | 13.8 |

| D7-508 | 16 | 7.94 | 19 | 35.5 | 508 | 2.5 |

| D8-508 | 19.05 | 9.525 | 25.4 | 50.8 | 508 | 4.4 |

| D9-558 | 24.1 | 7.94 | 33 | 50.8 | 558 | 6.1 |

| D9-610 | 24.1 | 7.94 | 33 | 50.8 | DCX | 6.6 |

| ECORK4 | 10.17 | 7.52 | 19.41 | 38.2 | 76.2 | 0.34 |

| KCORK-4.25" | 14.3 | 9.5 | 19.1 | 31.75 | 108 | 0.44 |

| SCORK-4.25" | 25.4 | 7.9 | 28.6 | 50.8 | 108 | 1.1 |

| TCORK-4.25" | 25.4 | 6.4 | 28.6 | 38.1 | 108 | 0.84 |

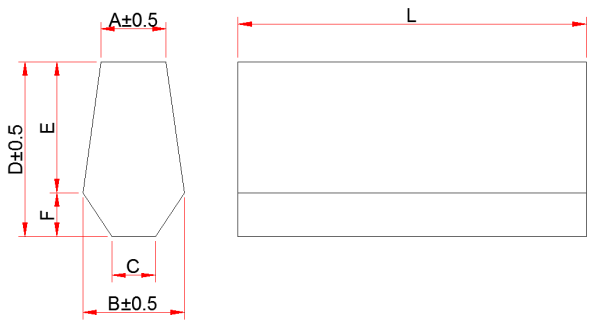

Materia diversa ad referentiam

Materia: 65Mn Duritia: HB300~HB320 Longitudo configurabilis, maxima 6000mm

| Numerus partis | A | B | C | D | E | F | L | W (kg) |

| BAR-C-3 | 14.3 | 22.2 | 9.53 | 38.11 | 28.58 | 9.53 | 76.2 | 0.405 |

| BAR-K-4 | 14.3 | 19.1 | 9.53 | 31.76 | 34.93 | 9.53 | 101.6 | 0.4075 |

| BAR-L-3 | 11.1 | 15.9 | 6.35 | 25.4 | 19.05 | 6.35 | 76.2 | 0.1974 |

| BAR-E-3 | 9.5 | 19.1 | 7.94 | 38.1 | 31.75 | 6.35 | 76.2 | 0.325 |

| BAR-A-3 | 9.5 | 15.9 | 6.35 | 34.93 | 28.58 | 6.35 | 76.2 | 0.261 |

Materia: 40Cr, Duritia: HB500, Fusio et tractatio caloris necessariae sunt.

| Numerus partis | A | B | C | D | E | F | L | W (kg) |

| ECORK 3 | 9.5 | 19.1 | 7.94 | 38.15 | 31.8 | 6.35 | 76.2 | 0.326 |

| GCORK 4 | 14.3 | 25.4 | 9.53 | 44.46 | 34.93 | 9.53 | 101.6 | 0.69 |

| JCORK 4 | 19.1 | 28.6 | 9.53 | 60.3 | 49.2 | 11.1 | 101.6 | 1.11 |

| ACORK 3 | 9.5 | 15.9 | 6.35 | 31.7 | 25.4 | 6.35 | 76.2 | 0.237 |

| WCORC 2.5 | 8 | 14.3 | 6.5 | 19.1 | 13.92 | 5.18 | 63.5 | 0.105 |

| KCORK 4 | 14.3 | 19.1 | 9.53 | 31.76 | 22.23 | 9.53 | 101.6 | 0.405 |

| HCORK 4 | 15.9 | 25.4 | 9.53 | 52.39 | 41.28 | 11.11 | 101.6 | 0.835 |

| CCORK 3 | 14.3 | 22.2 | 9.52 | 38.1 | 28.58 | 9.52 | 76.2 | 0.405 |

Materia: 42CrMoNi Duritia: HB500-550 Fusio et tractatio caloris necessariae sunt.

| Numerus partis | A | B | C | D | E | F | L | W (kg) |

| D9-610 | 24.1 | 33 | 7.94 | 50.8 | 41.28 | 9.53 | DCX | 6.6 |

| D10-610 | 28.58 | 38.1 | 14.29 | 66.68 | 57.15 | 9.53 | DCX | 10.4 |

- QUAE FORMA TUO VESTITU OPTIME CONVENIT?

VECTIS RECTA

- Forma detritionis aequabilis est per totam viam

- Calceus ad superficiem planam tondetur

- Bene operatur cum machinis ferrariarum automaticis

Vectis fusa

- Forma detritionis rotundata cum marginibus graviter detritis

- Necessitatem tondendi tollit

- Extrema vectis ad angulum 45 graduum praeciditur ad minorem resistentiam conversionis et ad maiorem firmamentum.

- Extrema vectis hamata ad calceos cursus aptandos designata sunt, marginibus graviter detritis.

- Idoneum calceis in agro conglutinatis

Vectis Curvata

- Forma detritionis leviter rotundata

- Necessitatem tondendi tollit

- Forma curvata virgae quantitatem suturae implendae requisitam minuit.

- Idoneum calceis in agro conglutinatis

Vectis obliqua

- Forma detritionis aequabilis est per totam viam

- Calceus ad superficiem planam tondetur

- Extrema vectis ad angulum 45 graduum praeciditur ad minorem resistentiam conversionis et ad maiorem firmamentum.

- Bene operatur cum machinis ferrariarum automaticis